Coating ink additive professional manufacturer

No.160-11,Xiangyuan Road,Jingjin Science and Technology Valley Inductrial Park,Wuqing District,Tianjin Province,China

jeffrey@rk-chem.com

+86 18526852692

Bis -[3-(triethoxysilicon) propyl] -disulfide

RK-G75

Product description

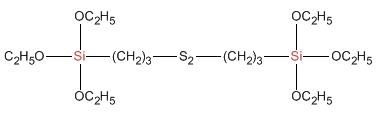

Structural formula:

Molecular formula: C18H42O6S2Si2

Molecular weight: 474.82

CAS No. : 56706-10-6

Chemical name: bis -[3-(triethoxysilicon) propyl] -disulfide

peculiarity

Yellow liquid, soluble in low alcohols, ketones, benzene, toluene, acetonitrile, chlorinated hydrocarbons, dimethylformamide, dimethyl sulfoxide; Insoluble in water.

Physical and chemical data

PROPERTIES | SPECIFICATION | TEST METHOD |

Appearance | Light yellow clear liquid | |

Sulfur Content(%) | 13.3-15.5 | ASTM D6741 |

Specific Gravity (20℃,g/cm3) | 1.03±0.02 | GB/T 4472 |

S2 Content HPLC(%) | 85.0±5.0 | ASTM D6844 |

Average Sulfur Chain Length (%) | 2.20±0.15 | ASTM D6844 |

Note: The above data is for reference only and cannot be used as technical specifications

Product introduction and application

The product has a specific sulfur chain distribution, and its appearance improves the processing defects of tetrathionosilane used in white carbon black-rubber system in the past, improves the productivity of rubber processing industry, and has the potential to replace tetrathionosilane. In the past, polysulfide compounds were easily desulphurized to form free sulfur in the high temperature mixing process higher than 150℃. The appearance of free sulfur made the high temperature mixing process produce vulcanization effect, resulting in gelation of the rubber mixing system, reducing the rheology of the system, and seriously leading to the decline of processing performance. However, if the mixing temperature is too low, it will lead to incomplete reaction between the silyl alcohol group and the silane coupling agent on the surface of white carbon black, resulting in insufficient reinforcement effect, and the dispersion of white carbon black in rubber is not good, and the silyl alcohol group on the surface of white carbon black reacts with the silane coupling agent to produce ethanol can not be completely evaporated, and the remaining ethanol will form bubbles during the extrusion process. Therefore, in the past, when the silane coupling agent was used to reinforce white carbon black, it had to be mixed in multiple steps at 150 ° C, which inevitably reduced productivity. The appearance of disulfide silane coupling agent completely avoids the above deficiencies. The specific distribution characteristics of the sulfur chain ensure the high temperature stability of the product, and avoid the formation of free sulfur in the process of high temperature mixing. It ensures that the silane coupling agent and white carbon black can fully react at temperatures above 150 ° C, and at the same time complete uniform dispersion in the rubber without affecting the processing performance. In this way, the production efficiency of the processing process is greatly improved, and the rubber product has excellent low heat generation and wear resistance properties. The excellent physical and chemical properties and processing properties of the product not only improve the physical properties of the rubber product, but also reduce the production cost of the rubber product.

Footwear - Improves wear resistance - improves cut resistance and pressure resistance - improves bending

Roller - improve wear resistance - improve aging resistance - improve process performance - improve bearing capacity - reduce water absorption - reduce hysteresis

Mechanical casting products - Enhanced modulus - enhanced thermal aging properties - Reduced compression devices - improved dynamic properties - Reduced expansion to polar solvents - substitution of fillers (non-black fillers instead of carbon black)

Hose - improve the wear resistance of the exterior - enhance the thermal aging performance - enhance the modulus - reduce the compression device - enhance the adhesion between the reinforcers Solid tire - improve the wear resistance - reduce the lag - enhance the modulus

Solid tires - improve wear resistance - reduce hysteresis - enhance modulus - improve process performance - maximize bonding performance

Tire - Improved tread wear resistance and thermal cracking - Improved adhesion of body and filler - Improved adhesion of tire buffer layer Flat tape - Improved wear resistance - improved vulcanization resistance - Reduced cost of clay instead of carbon black - Improved adhesion of tire fabric - Increased flexural life and modulus V-belt - Enhanced modulus - improved wear resistance - increased flexural life - improved adhesion of reinforced material

Product security, handling and storage

The container should be sealed after opening to prevent water vapor from entering and producing hydrolysis.

Stored in the original unopened container at room temperature, this product has a shelf life of one year from the date of production. After passing the test, the buyer will decide whether to continue to use the expired product.

Note: The Company is only responsible for the sales specifications of the products at the time of shipment, and shall not be liable for any indirect or incidental damages.

Packing :25L,200L,1000L

Q1: What can you buy from us?

A1: coating additive, ink additive, adhesive additive, composite additive.

Q2: How do I place an order?

A2: You can contact us by email with your order details.

Q3: How can I pay for you?

A3: We will ask you for payment after you confirm our PI. T/Tare our usual methods.

Q4: What's your delivery time?

A4: Usually we arrange shipment within 10 to 15 days.

Q5: Is this your real price?

A5: Yes, but the price is subject to the fluctuation of raw materials. I suggest you contact us before placing an order

Q6: How can we get the sample and how much will it cost?

A6: Our company provides free samples. You only need to pay the freight.

Just feel free to contact us,we will try our best to service you.

Ruike’ growing reputation in the industry is largely attributed to its commitment to provide a wide range of products and highly specialized service.

No.160-11,Xiangyuan Road,Jingjin Science and Technology Valley Inductrial Park,Wuqing District,Tianjin Province,China

jeffrey@rk-chem.com

+86 18526852692