Coating ink additive professional manufacturer

No.160-11,Xiangyuan Road,Jingjin Science and Technology Valley Inductrial Park,Wuqing District,Tianjin Province,China

jeffrey@rk-chem.com

+86 18526852692

Vinyl triethoxysilane

RK-G151

Product description

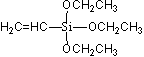

Structural formula:

Molecular formula: C8H18O3Si

Molecular weight: 190.3

CAS No. : 78-08-0

Chemical name: vinyl triethoxysilane

peculiarity

RK-G151 is a difunctional silane containing unsaturated double bonded vinyl groups and hydrolyzable inorganic ethoxysilane. The dual nature of its reaction enables it to bond inorganic materials and organic compounds together.

l ² has free radical chemical reaction activity.

l ² has hydrosilylation activity.

l ² The siloxane crosslinked structure is formed by wet crosslinking.

l ² Bonded to inorganic surfaces by alkoxy silyl groups.

Physical and chemical data

nature | Numerical value |

appearance | Colorless transparent liquid |

purity | ≥98.0% |

Density 20℃g/ml | 0.9060-0.9160 |

Boiling point 760mmHg | 161℃ |

Closed cup flash point | 34℃ |

Refractive index 25℃ | 1.3920-1.402 |

Note: The above data is for reference only and cannot be used as technical specifications

Reaction property

In the presence of water, RK-G151 will hydrolyze the silicon hydroxyl groups that produce domestic waves and form bonds on the surface of various inorganic materials.

Polymerization and copolymerization. The vinyl groups in RK-G151 can undergo radical polymerization.

Hydrosilylation reaction. The vinyl group in RK-G151 can be bonded with hydrogen silicon for hydrosilylation reaction.

Product application

1, packing treatment

As a coupling agent, it is used to improve the affinity between glass fibers, inorganic fillers and resins that react to vinyl, and strengthen polyester resins.

2, thermoplastic plastics

RK-G151 is commonly used in silane crosslinked polyethylene cables and pipes. During the extrusion process, RK-G151 can be grafted to the polymer under the action of a peroxide initiator. This silane graft material can be cross-linked by boiling, steam bath or absorbing water vapor in the air, thus transforming the original thermoplastic resin into a thermosetting resin. Silane crosslinked polymers have better heat resistance, mechanical strength and chemical resistance than the original thermoplastic resins, such as XLPE is an ideal material for cable insulation and hot water pipe materials.

Silane coupling agent RK-G151 is suitable for polyethylene copolymers of all kinds of complex shapes and densities, suitable for large processing tolerance, filled composite materials, etc., with high service temperature, excellent pressure cracking resistance, memory, wear resistance and impact resistance.

3, polymer modification

Silicone modified polymer (such as acrylic emulsion, styrene butadiene latex, etc.) is prepared as a copolymer to improve the water resistance, adhesion and scrub resistance of the modified polymer.

4. Sealant

Used in sealants, cross-linked by moisture to improve adhesion, chemical resistance, packing dispersion and aging resistance. For example, in the polybutadiene plastic sealing material, the filler quartz powder is treated with RK-G151 to improve the three-way combination of the surface of the polybutadiene resin and quartz powder, and enhance the density of the plastic, so as to improve the moisture resistance of the plastic sealing material. Alkoxy terminated silicone oil can be synthesized by silohydroaddition reaction to produce RTV-1, which is environmentally friendly and deethanolized.

5. Hydrophobic agent and surface protection

Used as the surface moisture treatment of electronic components, it can be used in the surface moisture treatment of circular fine-tuning porcelain dielectric capacitors against high voltage composite dielectric capacitors, improve the moisture resistance and surface finish of the product, and improve the product pass rate.

Product security, handling and storage

The container should be sealed after opening to prevent water vapor from entering and producing hydrolysis.

Stored in the original unopened container at room temperature, this product has a shelf life of one year from the date of production. After passing the test, the buyer will decide whether to continue to use the expired product.

Note: The Company is only responsible for the sales specifications of the products at the time of shipment, and shall not be liable for any indirect or incidental damages.

Packing :5L,10L,25L,200L,1000L

Q1: What can you buy from us?

A1: coating additive, ink additive, adhesive additive, composite additive.

Q2: How do I place an order?

A2: You can contact us by email with your order details.

Q3: How can I pay for you?

A3: We will ask you for payment after you confirm our PI. T/Tare our usual methods.

Q4: What's your delivery time?

A4: Usually we arrange shipment within 10 to 15 days.

Q5: Is this your real price?

A5: Yes, but the price is subject to the fluctuation of raw materials. I suggest you contact us before placing an order

Q6: How can we get the sample and how much will it cost?

A6: Our company provides free samples. You only need to pay the freight.

Just feel free to contact us,we will try our best to service you.

Ruike’ growing reputation in the industry is largely attributed to its commitment to provide a wide range of products and highly specialized service.

No.160-11,Xiangyuan Road,Jingjin Science and Technology Valley Inductrial Park,Wuqing District,Tianjin Province,China

jeffrey@rk-chem.com

+86 18526852692